Xinjiang Petroleum Geology ›› 2025, Vol. 46 ›› Issue (6): 754-761.doi: 10.7657/XJPG20250611

• RESERVOIR ENGINEERING • Previous Articles Next Articles

LIN Jiaying1a( ), QI Hongyan1a,2, CHANG Ting1a, ZHANG Yunjie1a, ZHANG Hao1a, CHEN Gang1a, LIANG Chenggang1b, WEI Xiaochen3

), QI Hongyan1a,2, CHANG Ting1a, ZHANG Yunjie1a, ZHANG Hao1a, CHEN Gang1a, LIANG Chenggang1b, WEI Xiaochen3

Received:2025-04-25

Revised:2025-08-12

Online:2025-12-01

Published:2025-12-05

CLC Number:

LIN Jiaying, QI Hongyan, CHANG Ting, ZHANG Yunjie, ZHANG Hao, CHEN Gang, LIANG Chenggang, WEI Xiaochen. Numerical Simulation of Strike-Slip Fault Induced Casing Deformation and Optimization of Fracturing Scheme: A Case Study of Shale Oil in Jimsar Sag[J]. Xinjiang Petroleum Geology, 2025, 46(6): 754-761.

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

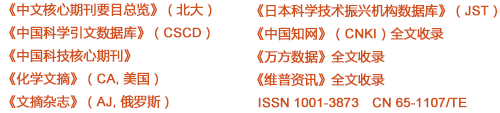

Table 2.

Fault activity coefficient and casing deformation risk level at well-fault intersections on Pad 71-73"

| 井名 | 井与断裂交叉点 测量深度/m | 2023年6月17日 | 2023年8月22日 | ||

|---|---|---|---|---|---|

| 断裂活动 系数 | 风险 等级 | 断裂活动 系数 | 风险 等级 | ||

| 71-16井 | 4 641 | 1.3 | 2 | 1.1 | 2 |

| 71-17井 | 4 827 | 1.9 | 1 | 3.0 | 1 |

| 71-36井 | 4 601 | 1.1 | 2 | 0.8 | 2级以上 |

| 71-37井 | 4 697 | 1.6 | 2 | 2.2 | 2 |

| 72-13井 | 4 493 | 0.8 | 2级以上 | 42.5 | 1 |

| 72-15井 | 4 190 | 1.5 | 2 | 5.9 | 2级以上 |

| 72-31井 | 4 627 | 2.6 | 1 | 3.5 | 1 |

| 72-33井 | 5 807 | 1.2 | 2级以上 | 4.0 | 1 |

| 72-35井 | 5 437 | 2.2 | 1 | 4.4 | 1 |

| 72-36井 | 4 265 | 1.2 | 2级以上 | 1.1 | 2级以上 |

| 73-31井 | 4 987 | 1.6 | 2 | 3.9 | 2级以上 |

| [1] | 杨海军, 能源, 邵龙飞, 等. 塔里木盆地台盆区走滑断裂带多层叠加样式及石油地质意义[J]. 新疆石油地质, 2024, 45(4):387-400. |

| YANG Haijun, NENG Yuan, SHAO Longfei, et al. Multilayer superimposition patterns of strike-slip fault zones and their petroleum geological significance in platform area,Tarim Basin[J]. Xinjiang Petroleum Geology, 2024, 45(4):387-400. | |

| [2] |

孟胡, 申颖浩, 朱万雨, 等. 四川盆地昭通页岩气水平井水力压裂套管外载分析[J]. 特种油气藏, 2023, 30(5):166-174.

doi: 10.3969/j.issn.1006-6535.2023.05.022 |

| MENG Hu, SHEN Yinghao, ZHU Wanyu, et al. External load analysis of hydraulic fracturing casing in Zhaotong shale gas horizontal well of Sichuan Basin[J]. Special Oil & Gas Reservoirs, 2023, 30(5):166-174. | |

| [3] | 童亨茂, 张平, 张宏祥, 等. 页岩气水平井开发套管变形的地质力学机理及其防治对策[J]. 天然气工业, 2021, 41(1):189-197. |

| TONG Hengmao, ZHANG Ping, ZHANG Hongxiang, et al. Geomechanical mechanisms and prevention countermeasures of casing deformation in shale gas horizontal wells[J]. Natural Gas Industry, 2021, 41(1):189-197. | |

| [4] | 王剑, 刘金, 潘晓慧, 等. 吉木萨尔凹陷芦草沟组页岩油生烃母质及其生烃机理[J]. 新疆石油地质, 2024, 45(3):253-261. |

| WANG Jian, LIU Jin, PAN Xiaohui, et al. Precursor and mechanism of hydrocarbon generation for shale oil in Lucaogou formation,Jimsar sag[J]. Xinjiang Petroleum Geology, 2024, 45(3):253-261. | |

| [5] |

侯冰, 常智, 武安安, 等. 吉木萨尔凹陷页岩油密切割压裂多簇裂缝竞争扩展模拟[J]. 石油学报, 2022, 43(1):75-90.

doi: 10.7623/syxb202201007 |

|

HOU Bing, CHANG Zhi, WU An’an, et al. Simulation of competitive propagation of multi-fractures on shale oil reservoir multi-clustered fracturing in Jimsar sag[J]. Acta Petrolei Sinica, 2022, 43(1):75-90.

doi: 10.7623/syxb202201007 |

|

| [6] | 魏海峰. 非均质性页岩水力压裂裂缝扩展形态研究进展[J]. 油气地质与采收率, 2023, 30(4):156-166. |

| WEI Haifeng. Research progress on fracture propagation patterns of hydraulic fracturing in heterogeneous shale[J]. Petroleum Geology and Recovery Efficiency, 2023, 30(4):156-166. | |

| [7] | 王孔阳. 页岩储层水力压裂诱发断层错动规律及套管损坏特征研究[D]. 北京: 中国石油大学(北京), 2022. |

| WANG Kongyang. Study on fault slip law and casing deformation characteristics induced by hydraulic fracturing in shale reservoir[D]. Beijing: China University of Petroleum (Beijing), 2022. | |

| [8] | 梁卫卫, 党海龙, 刘滨, 等. 特低渗透油藏注水诱导动态裂缝实验及数值模拟[J]. 石油实验地质, 2023, 45(3):566-575. |

| LIANG Weiwei, DANG Hailong, LIU Bin, et al. Experiment and numerical simulation of water injection induced dynamic fractures in ultra-low permeability reservoirs[J]. Petroleum Geology & Experiment, 2023, 45(3):566-575. | |

| [9] | 李晓, 郭鹏, 胡彦智, 等. 陆相页岩压裂试验与数值模拟:以鄂尔多斯盆地三叠系延长组7段为例[J]. 石油与天然气地质, 2023, 44(4):1009-1019. |

| LI Xiao, GUO Peng, HU Yanzhi, et al. Experiment and numerical simulation of hydraulic fracturing in lacustrine shale:Taking the Ordos Basin as an example[J]. Oil & Gas Geology, 2023, 44(4):1009-1019. | |

| [10] | 邹清腾, 曹博文, 王永红, 等. 考虑压裂诱导效应的页岩储层工程可压裂性评价[J]. 大庆石油地质与开发, 2024, 43(6):155-162. |

| ZOU Qingteng, CAO Bowen, WANG Yonghong, et al. Engineering fracability evaluation of shale reservoirs considering fracturing induced effect[J]. Petroleum Geology & Oilfield Development in Daqing, 2024, 43(6):155-162. | |

| [11] | 范宇, 黄锐, 曾波, 等. 四川页岩气水力压裂诱发断层滑动和套管变形风险评估[J]. 石油科学通报, 2020, 5(3):366-375. |

| FAN Yu, HUANG Rui, ZENG Bo, et al. Fault slip induced by hydraulic fracturing and risk assessment of casing deformation in the Sichuan Basin[J]. Chinese Petroleum Science Bulletin, 2020, 5(3):366-375. | |

| [12] | 刘金, 王剑, 张晓刚, 等. 准噶尔盆地吉木萨尔凹陷芦草沟组甜点页岩油微观赋存特征及成因机制[J]. 地质论评, 2022, 68 (3):907-920. |

| LIU Jin, WANG Jian, ZHANG Xiaogang, et al. Microscopic occurrence characteristics and genetic mechanism of shale oil in sweet spot reservoir of the Lucaogou formation in Jimsar sag[J]. Geological Review, 2022, 68(3):907-920. | |

| [13] | 高雅琪, 史保平. 基于速率-状态摩擦定律研究剪切应力扰动对地震断层演化的影响[J]. 地球物理学报, 2022, 65(6):2153-2166. |

| GAO Yaqi, SHI Baoping. Shear stress loading perturbation on the earthquake faulting based on the rate- and state-dependent friction law[J]. Chinese Journal of Geophysics, 2022, 65(6):2153-2166. | |

| [14] | 郭婷, 郝亚杰, 韩慧茹, 等. 煤炭可持续发展的变异系数和灰色关联分析[J]. 内蒙古煤炭经济, 2025, 43(3):71-73. |

| GUO Ting, HAO Yajie, HAN Huiru, et al. Coefficient of variation and grey correlation analysis of sustainable development of coal[J]. Inner Mongolia Coal Economy, 2025, 43(3):71-73. | |

| [15] | 庞涛, 姜在炳, 惠江涛, 等. 煤系水平井定向射孔压裂裂缝扩展机制[J]. 煤田地质与勘探, 2024, 52(4):68-75. |

| PANG Tao, JIANG Zaibing, HUI Jiangtao, et al. Fracture propagation mechanism in directional perforation and hydraulic fracturing of coal seam horizontal wells[J]. Coal Geology & Exploration, 2024, 52(4):68-75. | |

| [16] | 刘创新, 高红艳, 秦德文, 等. 地应力-岩石力学分析在东海低渗透致密砂岩气藏水平井压裂中的应用[J]. 世界石油工业, 2024, 31(3):78-89. |

| LIU Chuangxin, GAO Hongyan, QIN Dewen, et al. In-situ stress and rock mechanics analysis in the application of hydraulic fracturing for horizontal wells in the low-permeability and tight sandstone gas reservoirs of the East China Sea[J]. World Petroleum Industry, 2024, 31(3):78-89. | |

| [17] |

闫建平, 来思俣, 郭伟, 等. 页岩气井地质工程套管变形类型及影响因素研究进展[J]. 岩性油气藏, 2024, 36(5):1-14.

doi: 10.12108/yxyqc.20240501 |

|

YAN Jianping, LAI Siyu, GUO Wei, et al. Research progress on casing deformation types and influencing factors in geological engineering of shale gas wells[J]. Lithologic Reservoirs, 2024, 36(5):1-14.

doi: 10.12108/yxyqc.20240501 |

|

| [18] | 任佳伟, 白晓虎, 唐思睿, 等. 基于地质工程一体化的致密油井间干扰分析及井间距优化[J]. 地质科技通报, 2024, 43(6):271-280. |

| REN Jiawei, BAI Xiaohu, TANG Sirui, et al. Interwell interference analysis and well spacing optimization of tight oil wells based on geological engineering integration[J]. Bulletin of Geological Science and Technology, 2024, 43(6):271-280. | |

| [19] | 金亦秋, 赵群, 牟易升, 等. 泸州地区深层页岩气水平井套变成因机理探讨[J]. 天然气工业, 2024, 44(2):99-110. |

| JIN Yiqiu, ZHAO Qun, MOU Yisheng, et al. Discussion on formation mechanism of casing deformation in horizontal wells in deep shale gas of Luzhou area[J]. Natural Gas Industry, 2024, 44(2):99-110. | |

| [20] | 陈朝伟, 周文高, 项德贵, 等. 预防页岩气套管变形的橡胶组合套管研制及其抗剪切性能评价[J]. 天然气工业, 2023, 43(11):131-136. |

| CHEN Zhaowei, ZHOU Wengao, XIANG Degui, et al. Development of rubber composite casing for preventing shale gas casing deformation and its shear resistance evaluation[J]. Natural Gas Industry, 2023, 43(11):131-136. | |

| [21] |

韩玲玲, 李熙喆, 刘照义, 等. 川南泸州深层页岩气井套管变形主控因素与防控对策[J]. 石油勘探与开发, 2023, 50(4):853-861.

doi: 10.11698/PED.20230032 |

| HAN Lingling, LI Xizhe, LIU Zhaoyi, et al. Influencing factors and prevention measures of casing deformation in deep shale gas wells in Luzhou block,southern Sichuan Basin,SW China[J]. Petroleum Exploration and Development, 2023, 50(4):853-861. |

| [1] | ZHANG Rujie, YUE Ping, ZHANG Ying, LI Xiaobo, HUANG Nan, ZHAO Liming2, FAN Qingzhen. Numerical Simulation of Grid-Like Fragmented Structure of Fault-Karst Reservoirs in Southern Tuoputai Block [J]. Xinjiang Petroleum Geology, 2025, 45(zk(English)): 132-137. |

| [2] | JIN Zhijun, CAO Yan, ZHANG Hong, TANG Yong, QIN Zhijun, LIU Kouqi, LIANG Chenggang, LI Guanfang, HE Wenjun. Main Controlling Factors and Development Practice of Shale Oil Sweet Spots in the Lucaogou Formation, Jimsar Sag, Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 647-658. |

| [3] | MAO Xinjun, WANG Ran, ZHENG Menglin, LI Jing, PAN Jin, WANG Tao, HUANG Liliang, CHANG Qiusheng. Pore Genesis and Diagenetic Evolution of Shale Oil Sweet Spot Reservoirs in Lucaogou Formation, Jimsar Sag [J]. Xinjiang Petroleum Geology, 2025, 46(6): 659-667. |

| [4] | CAO Jian, QIN Zhijun, WEI Chao, XIANG Baoli, LIU Jin. Source-Reservoir Coupling and Sweet Spot Formation Mechanism of Continental Laminated Shale Oil: A Case Study of the Fengcheng Formation, Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 668-683. |

| [5] | LIU Jin, BAI Lei, ZHANG Baozhen, WEI Chao, LEI Haiyan, DENG Yuan, CAO Jian. Microscopic Occurrence and Production Dynamics of Shale Oil in Lucaogou Formation, Jimsar Sag, Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 684-692. |

| [6] | ZOU Yang, CHEN Wenshun, LUO Gang, CHEN Shaorong, CHEN Fangwen, HE Wenjun, LIU Xinlong, ZHU Tao. Main Factors Controlling the Enrichment and High Production of Alkaline Lacustrine Shale Oil in Fengcheng Formation, Mahu Sag, Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 693-702. |

| [7] | WEI Zhaosheng, QI Hongyan, ZHAO Jianfei, HE Jixiang, LIU Kecheng, WANG Junchao. Development Progress and Key Technologies for Cost-Effective Productivity of Shale Oil in Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 703-711. |

| [8] | LI Qing, LUO Gang, LI Yingyan, DENG Yuan, XIAO Dianshi, XIE Xiaoquan. Potential of Replacement Areas for Shale Oil Development in the Lucaogou Formation, Jimsar Sag [J]. Xinjiang Petroleum Geology, 2025, 46(6): 712-722. |

| [9] | LIU Xiangjun, GAN Renzhong, XIONG Jian, TANG Shiqi, WAN Youwei, ZHOU Xin, LIANG Lixi, ZHANG Miao. Dominant Geomechanical Factors Controlling the Volumetric Stimulation Effectiveness in the Shale Oil Reservoirs of the Lucaogou Formation, Jimsar Sag [J]. Xinjiang Petroleum Geology, 2025, 46(6): 723-733. |

| [10] | QI Hongyan, WANG Zhenlin, ZHENG Guoqing, YU Peirong, YANG Wangwang. Unbalanced Fracture Propagation Mechanism During Horizontal Well Intensive Fracturing in Shale Oil Reservoirs [J]. Xinjiang Petroleum Geology, 2025, 46(6): 734-741. |

| [11] | LI Yingyan, DING Yi, LUO Gang, DING Huaiyu, TANG Huiying, HE Ge. Collaborative Optimization of Well Pattern-Fracture Network Based on Geology-Engineering Integration Simulation:A Case Study of Shale Oil in the Jimsar Sag, Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 742-753. |

| [12] | DU Xuebiao, ZHANG Jinfeng, XIAO Dianshi, RAN Yang, LIU Yingjie, QIN Jiamin, WANG Liangzhe. NMR Effective Porosity Spectrum Prediction and Resolution Matching Based on ReliefF and LSBoost Ensemble Tree [J]. Xinjiang Petroleum Geology, 2025, 46(6): 762-772. |

| [13] | YAO Juqin, CHEN Gang, TANG Tingming, ZHAO Chunxue, LI Wei, YU Xuefeng, YU Jianglong. Application of Seismic Frequency-Increasing Method Based on Point Complex Spectrum in Shale Oil Sweet Spot Prediction, Jimsar Sag, Junggar Basin [J]. Xinjiang Petroleum Geology, 2025, 46(6): 773-778. |

| [14] | MAO Rui, WEI Jiamin, WANG Pan, LI Qingqing, ZHAO Lei. Logging-Based Evaluation of Key Parameters of Shale Oil Reservoirs in Fengcheng Formation, Mahu Sag [J]. Xinjiang Petroleum Geology, 2025, 46(6): 779-789. |

| [15] | LI Yanghu, WANG Zhenlin, SHAO Huanhuan, CHEN Shanhe, TANG Fukang, LIU Caiguang, WANG Wei, ZHANG Hao. Acoustic Anisotropy Correction Based on Clay Mineral Content in Shale Oil Horizontal Wells [J]. Xinjiang Petroleum Geology, 2025, 46(6): 790-799. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||