Xinjiang Petroleum Geology ›› 2024, Vol. 45 ›› Issue (4): 451-459.doi: 10.7657/XJPG20240409

• RESERVOIR ENGINEERING • Previous Articles Next Articles

LIU Qiang1,2,3( ), LI Jing4, LI Ting2,3,5, ZHENG Mingjun2,3,5, XU Mengjia2,3,5, WANG Xuan2,3,5, WU Mingyang4

), LI Jing4, LI Ting2,3,5, ZHENG Mingjun2,3,5, XU Mengjia2,3,5, WANG Xuan2,3,5, WU Mingyang4

Received:2024-04-08

Revised:2024-05-10

Online:2024-08-01

Published:2024-07-23

CLC Number:

LIU Qiang, LI Jing, LI Ting, ZHENG Mingjun, XU Mengjia, WANG Xuan, WU Mingyang. Oil-Water Two-Phase Flow Behaviors in Fracture-Cavity Carbonate Reservoirs With Fluid-Solid Coupling[J]. Xinjiang Petroleum Geology, 2024, 45(4): 451-459.

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

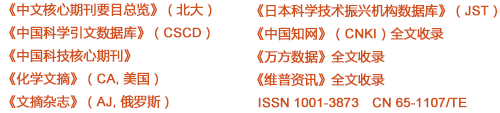

Table 1.

Parameters for numerical simulation"

| 参数 | 取值 | 参数 | 取值 |

|---|---|---|---|

| 基质初始渗透率/mD | 0.8 | 出口压力/MPa | 80 |

| 基质初始孔隙度 | 0.02 | 水相密度/(kg·m-3) | 1 000 |

| 基质弹性模量/GPa | 34 | 水相黏度/(mPa·s) | 1 |

| 基质泊松比 | 0.21 | 油相密度/(kg·m-3) | 800 |

| 基质Biot系数 | 0.8 | 油相黏度/(mPa·s) | 1.8 |

| 裂缝孔隙度 | 0.01 | 最大水平主应力/MPa | 180 |

| 裂缝初始渗透率/mD | 1×105 | 最小水平主应力/MPa | 150 |

| 裂缝初始开度/mm | 0.2 | 滑移系数/(m·s-1) | 0.1 |

| 裂缝法向刚度/GPa | 100 | 裂缝Biot系数 | 1 |

| 渗流耦合参数/Pa-1 | 1×10-6 | 注水速度/(m·s-1) | 0.1 |

| 初始地层压力/MPa | 80 | 水相、油相相渗指数 | 1 |

| [1] | 杨学文, 田军, 王清华, 等. 塔里木盆地超深层油气地质认识与有利勘探领[J]. 中国石油勘探, 2021, 26(4):17-28. |

| YANG Xuewen, TIAN Jun, WANG Qinghua, et al. Geological understanding and favorable exploration fields of ultra-deep formations in Tarim basin[J]. China Petroleum Exploration, 2021, 26(4):17-28. | |

| [2] |

田军, 杨海军, 朱永峰, 等. 塔里木盆地富满油田成藏地质条件及勘探开发关键技术[J]. 石油学报, 2021, 42(8):971-985.

doi: 10.7623/syxb202108001 |

| TIAN Jun, YANG Haijun, ZHU Yongfeng, et al. Geological conditions for hydrocarbon accumulation and key technologies for exploration and development in Fuman oilfield,Tarim basin[J]. Acta Petrolei Sinica, 2021, 42(8):971-985. | |

| [3] | 何治亮, 马永生, 朱东亚, 等. 深层-超深层碳酸盐岩储层理论技术进展与攻关方向[J]. 石油与天然气地质, 2021, 42(3):533-546. |

| HE Zhiliang, MA Yongsheng, ZHU Dongya, et al. Theoretical and technological progress and research direction of deep and ultra-deep carbonate reservoirs[J]. Oil & Gas Geology, 2021, 42(3):533-546. | |

| [4] | 李静, 刘晨, 刘惠民, 等. 复杂断层构造区地应力分布规律及其影响因素[J]. 中国矿业大学学报, 2021, 50(1):123-137. |

| LI Jing, LIU Chen, LIU Huimin, et al. Distribution and influencing factors of in-situ stress in complex fault tectonic region[J]. Journal of China University of Mining & Technology, 2021, 50(1):123-137. | |

| [5] | WILSON M, LEWIS D, YOGI O, et al. Development of a Papua New Guinean onshore carbonate reservoir:A comparative borehole image (FMI) and petrographic evaluation[J]. Marine and Petroleum Geology, 2013,44:164-195. |

| [6] | XAVIER A, GUERRA C E, ANDRADE A. Fracture analysis in borehole acoustic images using mathematical morphology[J]. Journal of Geophysics and Engineering, 2015, 12(3):492-501. |

| [7] | 李小波, 魏学刚, 刘学利, 等. 顺北油田超深断控缝洞型油藏注水开发实践[J]. 新疆石油地质, 2023, 44(6):702-710. |

| LI Xiaobo, WEI Xuegang, LIU Xueli, et al. Practice of water injection development in ultra-deep fault-controlled fractured-vuggy reservoirs in Shunbei oilfield[J]. Xinjiang Petroleum Geology, 2023, 44(6):702-710. | |

| [8] | 荣元帅, 李新华, 刘学利, 等. 塔河油田碳酸盐岩缝洞型油藏多井缝洞单元注水开发模式[J]. 油气地质与采收率, 2013, 20(2):58-61. |

| RONG Yuanshuai, LI Xinhua, LIU Xueli, et al. Discussion about pattern of water flooding development in multi-well fracture-cavity units of carbonate fracture-cavity reservoir in Tahe oilfield[J]. Petroleum Geology and Recovery Efficiency, 2013, 20(2):58-61. | |

| [9] | HOU Jirui, LI Haibo, YU Jiang, et al. Macroscopic three-dimensional physical simulation of water flooding in multi-well fracture-cavity unit[J]. Petroleum Exploration and Development, 2014, 41(6):784-789. |

| [10] | LI Yilong, WU Feng, LI Xiaoping, et al. Experimental study on waterflood development in large-scale karst structures[J]. Journal of Petroleum Science and Engineering, 2019,175:838-851. |

| [11] | ZHAO Yulong, LU Guang, ZHANG Leihui, et al. Physical simulation of waterflooding development in large-scale fractured-vuggy reservoir considering filling characteristics[J]. Journal of Petroleum Science and Engineering, 2020,191:107328. |

| [12] | JÄGER W, MIKELIC A. On the interface boundary condition of Beavers,Joseph,and Saffman[J]. SIAM Journal on Applied Mathematics, 2000, 60(4):1111-1127. |

| [13] | GIRAULT V, RIVIÈRE B. DG approximation of coupled Navier-Stokes and Darcy equations by Beaver-Joseph-Saffman interface condition[J]. Siam Journal on Numerical Analysis, 2009, 47(3):2052-2089. |

| [14] | 黄朝琴, 高博, 姚军. Stokes-Darcy耦合流动问题的交界面条件研究[J]. 中国科学:物理学力学天文学, 2014, 44(2):212-220. |

| HUANG Zhaoqin, GAO Bo, YAO Jun. On the interface boundary conditions for the Stokes-Darcy coupling problem[J]. Scientia Sinica Physica,Mechanica & Astronomica, 2014, 44(2):212-220. | |

| [15] | CAMAÑO J, GATICA N G, OYARZÚA R, et al. New fully-mixed finite element methods for the Stokes-Darcy coupling[J]. Computer Methods in Applied Mechanics and Engineering, 2015,295:362-395. |

| [16] | LIU Xin, LI Rui, CHEN Zhangxin. A virtual element method for the coupled Stokes-Darcy problem with the Beaver-Joseph-Saffman interface condition[J]. Calcolo, 2019, 56(4):48. |

| [17] | HAN Dazhi, HE Xiaoming, WANG Quan, et al. Existence and weak-strong uniqueness of solutions to the Cahn-Hilliard-Navier-Stokes-Darcy system in superposed free flow and porous media[J]. Nonlinear Analysis, 2021,211:112411. |

| [18] | LIU Lijun, HUANG Zhaoqin, YAO Jun, et al. Simulating two-phase flow and geomechanical deformation in fractured karst reservoirs based on a coupled hydro-mechanical model[J]. International Journal of Rock Mechanics and Mining Sciences, 2021,137:104543. |

| [19] | LIU Shun, ZHANG Yalong, DU Hengyi, et al. Experimental study on fluid flow behaviors of waterflooding fractured-vuggy oil reservoir using two-dimensional visual model[J]. Physics of Fluids, 2023, 35(6):062106. |

| [20] | WANG Jing, LIU Huiqing, NING Zhengfu, et al. Experiments on water flooding in fractured-vuggy cells in fractured-vuggy reservoirs[J]. Petroleum Exploration and Development, 2014, 41(1):74-81. |

| [21] | 王雷, 窦之林, 林涛, 等. 缝洞型油藏注水驱油可视化物理模拟研究[J]. 西南石油大学学报(自然科学版), 2011, 33(2):121-124. |

| WANG Lei, DOU Zhilin, LIN Tao, et al. Study on the visual modeling of water flooding in carbonate fracture-cavity reservoir[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2011, 33(2):121-124. | |

| [22] | 顾浩, 康志江, 尚根华, 等. 超深层断控缝洞型油藏油井合理产能优化方法及应用[J]. 新疆石油地质, 2023, 44(1):64-69. |

| GU Hao, KANG Zhijiang, SHANG Genhua, et al. Reasonable productivity optimization methods and application in ultra-deep fault-controlled fractured-vuggy reservoirs[J]. Xinjiang Petroleum Geology, 2023, 44(1):64-69. | |

| [23] | 刘礼军. 缝洞型碳酸盐岩油气藏流固耦合数值模拟研究[D]. 山东青岛: 中国石油大学(华东), 2021. |

| LIU Lijun. Numerical simulation of coupled flow and geomechanical process in fractured karst carbonate reservoirs[D]. Qingdao, Shandong: China University of Petroleum(East China), 2021. | |

| [24] | 刘承婷, 刘钢, 李家丞, 等. 基于Fluent与Hernandez模型的缝洞型油藏水驱油机理及影响因素分析[J]. 南京理工大学学报, 2019, 43(3):367-372. |

| LIU Chengting, LIU Gang, LI Jiacheng, et al. Analysis of mechanism and influential factors of water-driven-oil in fractured-vuggyreservoirs based on Fluent and Hernandez[J]. Journal of Nanjing University of Science and Technology, 2019, 43(3):367-372. | |

| [25] | 陈海波. 流固耦合作用下粗糙裂隙岩体渗流及滑移失稳机理研究[D]. 太原: 太原理工大学, 2023. |

| CHEN Haibo. Study on seepage and slip instability mechanism of rough fractured rock mass under the action of fluid-deformation coupling[D]. Taiyuan: Taiyuan University of Technology, 2023. | |

| [26] | 张英. 水-力耦合作用下裂隙岩体渗流规律与突水机理研究[D]. 北京: 北京科技大学, 2020. |

| ZHANG Ying. Study on the seepage regularity and water inrush mechanism of fracture rock mass under coupling action of stress field and hydraulic force[D]. Beijing: University of Science and Technology Beijing, 2020. |

| [1] | XIONG Chang, SHEN Chunguang, ZHAO Xingxing, ZHAO Longfei, LI Shengqian, ZHOU Jie, PAN Tiancou. Segmentation of Strike-Slip Faults and Its Controls on Hydrocarbon Accumulation in Tarim Basin: A Case Study of FⅠ17 Strike-Slip Fault Zone [J]. Xinjiang Petroleum Geology, 2024, 45(4): 417-424. |

| [2] | LI Mohan, LI Xiangwen, DU Zhongyuan, ZHANG Yintao, JIN Meng, WANG Ziao. Establishment of Geological Model of Ancient Pockmarks in Fuman Oilfield, Tarim Basin [J]. Xinjiang Petroleum Geology, 2024, 45(4): 442-450. |

| [3] | WANG Rujun, SUN Chong, YUAN Jingyi, LIU Ruidong, WANG Xuan, MA Yinglong, WANG Xupeng. Seismic Identification of Strike-Slip Fault Damage Zones Based on Structure Tensor Analysis: A Case Study of Ultra-Deep Carbonate Rocks in Fuman Oilfield [J]. Xinjiang Petroleum Geology, 2024, 45(4): 475-482. |

| [4] | GENG Jie, YUE Ping, YANG Wenming, YANG Bo, ZHAO Bin, ZHANG Rujie. Dynamic Reserves Calculation Method for Fault-Controlled Carbonate Reservoirs [J]. Xinjiang Petroleum Geology, 2024, 45(4): 499-504. |

| [5] | SHI Lanxiang, TANG Wenjun, ZHOU You, WANG Bojun. Study on Water Flooding With Self-Emulsification in Heavy Oil Reservoirs [J]. Xinjiang Petroleum Geology, 2024, 45(2): 228-234. |

| [6] | ZHANG Rujie, YUE Ping, ZHANG Ying, LI Xiaobo, HUANG Nan, ZHAO Liming, FAN Qingzhen. Numerical Simulation of Grid-Like Fragmented Structure of Fault-Karst Reservoirs in Southern Tuoputai Block [J]. Xinjiang Petroleum Geology, 2024, 45(1): 58-64. |

| [7] | LI Xiaobo, WEI Xuegang, LIU Xueli, ZHANG Yixiao, LI Qing. Practice of Water Injection Development in Ultra-Deep Fault-Controlled Fractured-Vuggy Reservoirs in Shunbei Oilfield [J]. Xinjiang Petroleum Geology, 2023, 44(6): 702-710. |

| [8] | GENG Yudi, LIU Lijun, WANG Lijing, GUO Tiankui. Numerical Simulation of One-Hole Multi-Target Staged Fracturing in Fractured-Vuggy Reservoirs [J]. Xinjiang Petroleum Geology, 2023, 44(6): 711-719. |

| [9] | WANG Ting, WANG Jie, JIANG Houshun, XU Hualei, YAO Ziyi, NAN Chong. 3D Geological Simulation of Hydraulic Fracture Propagation and Frac-Hit Prevention in Horizontal Shale Gas Wells [J]. Xinjiang Petroleum Geology, 2023, 44(6): 720-728. |

| [10] | LYU Zhao, PAN Liyan, HAO Lihua, ZOU Nana, ZOU Zhikun. Numerical Simulation of Factors Influencing Hydraulic Fracture Propagation in Sandstone-Mudstone Interbedded Reservoirs [J]. Xinjiang Petroleum Geology, 2023, 44(6): 729-738. |

| [11] | XIE Peng, CHEN Pengyu, ZHAO Hailong, Xu Jianting. Water Invasion Characteristics and Residual Gas Distribution in Fractured-Porous Carbonate Reservoirs [J]. Xinjiang Petroleum Geology, 2023, 44(5): 583-591. |

| [12] | DUAN Yongxian, SONG Jinpeng, HUAN Zhipeng, YANG Liangang, ZHOU Peng, LV Duanchuan, TIAN Zhihong. Formation, Preservation and Distribution of Abnormally High Pressure in Ordovician Carbonate Rocks in Northern and Central Tarim Basin [J]. Xinjiang Petroleum Geology, 2023, 44(4): 421-428. |

| [13] | HU Wenge, LI Xiaobo, YANG Min, LU Xinbian, LIU Xueli, LIU Hongguang. Well Pattern Optimization for Fractured-Vuggy Carbonate Reservoirs in Tahe Oilfield [J]. Xinjiang Petroleum Geology, 2023, 44(4): 429-434. |

| [14] | HU Yong, LE Ping, GUO Chunqiu, CHEN Pengyu, XIAO Yun, QU Simin, WANG Xin. Experimental Study on Water Invasion in Full-Diameter Cores From Fractured Carbonate Reservoirs [J]. Xinjiang Petroleum Geology, 2023, 44(4): 479-484. |

| [15] | LIU Xueli, TAN Tao, CHEN Yong, XIE Hui, ZHU Suyang, WU Haoqiang, XIANG Dongliu. Development Characteristics of Solution-Gas Drive in Fault-Karst Reservoirs in Shunbei-1 Block [J]. Xinjiang Petroleum Geology, 2023, 44(2): 195-202. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||