Xinjiang Petroleum Geology ›› 2022, Vol. 43 ›› Issue (2): 214-220.doi: 10.7657/XJPG20220213

• APPLICATION OF TECHNOLOGY • Previous Articles Next Articles

WANG Quan( ), CHEN Chao, Hasyati SAYITI, ZHANG Yi, BAO Yingjun, WU Min

), CHEN Chao, Hasyati SAYITI, ZHANG Yi, BAO Yingjun, WU Min

Received:2021-02-25

Revised:2021-06-24

Online:2022-04-01

Published:2022-03-24

CLC Number:

WANG Quan, CHEN Chao, Hasyati SAYITI, ZHANG Yi, BAO Yingjun, WU Min. Early Warning Model for Critical Sand Production in Horizontal Wells Based on Pressure Monitoring: A Case of H Gas Storage in Xinjiang[J]. Xinjiang Petroleum Geology, 2022, 43(2): 214-220.

Add to citation manager EndNote|Reference Manager|ProCite|BibTeX|RefWorks

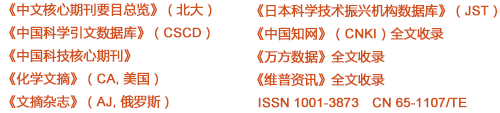

Table 2

Test results of critical sand production flow rate and pressure difference for horizontal wells in H gas storage"

| 井名 | 无阻流量/ (104 m3·d-1) | 测试地层 压力/ MPa | 临界出砂 流量/ (104 m3·d-1) | 临界出砂 压差/ MPa |

|---|---|---|---|---|

| HW4井 | 353 | 32.0 | 150 | 4.2 |

| HW5井 | 323 | 31.5 | 130 | 3.8 |

| HW6井 | 301 | 30.3 | 130 | 3.9 |

| HW11井 | 319 | 29.4 | 120 | 3.7 |

| HW12井 | 332 | 30.8 | 140 | 4.5 |

| [1] | 丁国生, 李春, 王皆明, 等. 中国地下储气库现状及技术发展方向[J]. 天然气工业, 2015, 35(11):107-112. |

| DING Guosheng, LI Chun, WANG Jieming, et al. The status quo and technical development direction of underground gas storages in China[J]. Natural Gas Industry, 2015, 35(11):107-112. | |

| [2] | 张刚雄, 李彬, 郑得文, 等. 中国地下储气库业务面临的挑战及对策建议[J]. 天然气工业, 2017, 37(1):153-159. |

| ZHANG Gangxiong, LI Bin, ZHENG Dewen, et al. Challenges to and proposals for underground gas storage (UGS) business in China[J]. Natural Gas Industry, 2017, 37(1):153-159. | |

| [3] | 郑得文, 张刚雄, 魏欢, 等. 中国天然气调峰保供的策略与建议[J]. 天然气工业, 2018, 38(4):153-160. |

| ZHENG Dewen, ZHANG Gangxiong, WEI Huan, et al. Countermeasures and suggestions on natural gas peak shaving and supply guarantee in China[J]. Natural Gas Industry, 2018, 38(4):153-160. | |

| [4] | 谢南星, 孙风景, 王威林, 等. 适用于大注采气量水平井注采能力测试的连续油管测试技术:以重庆相国寺地下储气库为例[J]. 天然气工业, 2019, 39(2):61-65. |

| XIE Nanxing, SUN Fengjing, WANG Weilin, et al. Coiled tubing testing technology for testing the injection-production capacity of horizontal wells with high gas injection-production rates:a case study of the Xiangguosi underground gas storage in Chongqing[J]. Natural Gas Industry, 2019, 39(2):61-65. | |

| [5] | 王彬, 陈超, 李道清, 等. 新疆H型储气库注采气能力评价方法[J]. 特种油气藏, 2015, 22(5):78-81. |

| WANG Bin, CHEN Chao, LI Daoqing, et al. A method for assessing the gas injection-production capacity of H-shaped UGS in Xinjiang oilfield[J]. Special Oil and Gas Reservoirs, 2015, 22(5):78-81. | |

| [6] | 罗天雨, 麻慧博, 艾尼瓦尔, 等. 呼图壁储气库合理生产压差数值分析[J]. 中外能源, 2011, 16(6):43-46. |

| LUO Tianyu, MA Huibo, AINIWAER, et al. The numerical analysis of reasonable producing pressure drop in Hutubi gas storage[J]. Sino-Global Energy, 2011, 16(6):43-46. | |

| [7] | 隋义勇, 林堂茂, 刘翔, 等. 交变载荷对储气库注采井出砂规律的影响[J]. 油气储运, 2019, 38(3):303-307. |

| SUI Yiyong, LIN Tangmao, LIU Xiang, et al. The influence of alternating load on sand production law of injection/production wells of underground gas storages[J]. Oil & Gas Storage and Transportation, 2019, 38(3):303-307. | |

| [8] | 孙贺东, 常宝华, 张静楠, 等. 裂缝性致密砂岩气藏出砂原因及对产气量的影响:以塔里木盆地克深气田为例[J]. 天然气工业, 2018, 38(11):52-58. |

| SUN Hedong, CHANG Baohua, ZHANG Jingnan, et al. Causes of sand production and its influence on the output of fractured tight sandstone gas reservoirs:a case study on the Keshen gas field,Tarim basin[J]. Natural Gas Industry, 2018, 38(11):52-58. | |

| [9] | 董长银, 张启汉, 饶鹏. 气井系统出砂预测模型研究及应用[J]. 天然气工业, 2005, 25(9):98-100. |

| DONG Changyin, ZHANG Qihan, RAO Peng. Model of systematic sanding prediction and its application for gas wells[J]. Natural Gas Industry, 2005, 25(9):98-100. | |

| [10] | 王嘉淮, 罗天雨, 吕毓刚, 等. 呼图壁地下储气库气井冲蚀产量模型及其应用[J]. 天然气工业, 2012, 32(2):57-59. |

| WANG Jiahuai, LUO Tianyu, LÜ Yugang, et al. Research and application of the model of gas well erosion output of the Hutubi underground gas storage[J]. Natural Gas Industry, 2012, 32(2):57-59. | |

| [11] | 唐立根, 王皆明, 丁国生, 等. 基于开发资料预测气藏改建储气库后井底流入动态[J]. 石油勘探与开发, 2016, 43(1):127-130. |

| TANG Ligen, WANG Jieming, DING Guosheng, et al. Downhole inflow-performance forecast for underground gas storage based on gas reservoir development data[J]. Petroleum Exploration and Development, 2016, 43(1):127-130. | |

| [12] | 陈超, 庞晶, 李道清, 等. 呼图壁储气库全周期交互注采动态评价方法[J]. 新疆石油地质, 2016, 37(6):709-714. |

| CHEN Chao, PANG Jing, LI Daoqing, et al. A method for full-cycle alternative injection-production performance evaluation of Hutubi underground gas storage[J]. Xinjiang Petroleum Geology, 2016, 37(6):709-714. | |

| [13] | 孙军昌, 胥洪成, 王皆明, 等. 气藏型地下储气库建库注采机理与评价关键技术[J]. 天然气工业, 2018, 38(4):138-144. |

| SUN Junchang, XU Hongcheng, WANG Jieming, et al. Injection-production mechanisms and key evaluation technologies for underground gas storages rebuilt from gas reservoirs[J]. Natural Gas Industry, 2018, 38(4):138-144. | |

| [14] | 陈显学, 温海波. 辽河油田双6储气库单井采气能力评价[J]. 新疆石油地质, 2017, 38(6):715-718. |

| CHEN Xianxue, WEN Haibo. Evaluation of single gas well production capacity of Shuang-6 gas storage in Liaohe oilfield[J]. Xinjiang Petroleum Geology, 2017, 38(6):715-718. | |

| [15] | BlASINGAME T A, JOHNSTON J L, LEE W J. Type-curve analysis using the pressure integral method[R]. SPE 18799,1989. |

| [16] | 唐立根, 王皆明, 白凤娟, 等. 基于修正后的物质平衡方程预测储气库库存量[J]. 石油勘探与开发, 2014, 41(4):480-484. |

| TANG Ligen, WANG Jieming, BAI Fengjuan, et al. Inventory forecast in underground gas storage based on modified material balance equation[J]. Petroleum Exploration and Development, 2014, 41(4):480-484. | |

| [17] | 王泉, 陈超, 李道清, 等. 基于有效渗透率的单井增产潜力定量评价:以新疆H储气库为例[J]. 新疆石油地质, 2020, 41(4):450-456. |

| WANG Quan, CHEN Chao, LI Daoqing, et al. Quantitative evaluation of well yield-increasing potential based on effective permeability:a case of H gas storage in Xinjiang[J]. Xinjiang Petroleum Geology, 2020, 41(4):450-456. | |

| [18] | 胡文革. 顺北油气田断溶体油藏油井产能评价新方法[J]. 新疆石油地质, 2021, 42(2):168-172. |

| HU Wenge. A new method for evaluating the productivity of oil wells in fault-karst reservoirs in Shunbei oil & gas field[J]. Xinjiang Petroleum Geology, 2021, 42(2):168-172. | |

| [19] | 陈元千. 气井垂直管流计算方法的推导与应用[J]. 断块油气田, 2010, 17(4):443-447. |

| CHEN Yuanqian. Derivation and application of calculating methods of vertical pipe fiow in gas wells[J]. Fault-Block Oil & Gas Field, 2010, 17(4):443-447. | |

| [20] | 王彦利, 陈小凡, 邓生辉, 等. 疏松砂岩临界出砂压差的计算方法研究及应用[J]. 西南石油大学学报(自然科学版), 2009, 31(1):78-80. |

| WANG Yanli, CHEN Xiaofan, DENG Shenghui, et al. The calculation method study and application of the critical sand production pressure difference in loose sandstone[J]. Journal of Southwest Petroleum University(Science & Technology Edition), 2009, 31(1):78-80. | |

| [21] | 王小鲁, 杨万萍, 严焕德, 等. 疏松砂岩出砂机理与出砂临界压差计算方法[J]. 天然气工业, 2009, 29(7):72-75. |

| WANG Xiaolu, YANG Wanping, YAN Huande, et al. The sanding mechanism and sanding critical drawdown calculation in loose sandstone[J]. Natural Gas Industry, 2009, 29(7):72-75. | |

| [22] | 熊友明, 潘迎德. 产层岩石坚固程度判断指标“C”公式及其应用[J]. 西南石油学院学报, 1994, 16(2):67-73. |

| XIONG Youming, PAN Yingde. The criterion “C” formula determing wellbore solidity and its application[J]. Journal of Southwest Petroleum Institute, 1994, 16(2):67-73. |

| [1] | YU Peirong, ZHENG Guoqing, SUN Futai, WANG Zhenlin. Simulation on Fracture Propagation During Hydraulic Fracturing in Horizontal Wells in Shale Reservoirs of Fengcheng Formation,Mahu Sag [J]. Xinjiang Petroleum Geology, 2022, 43(6): 750-756. |

| [2] | SONG Junqiang, LI Xiaoshan, WANG Shuo, GU Kaifang, PAN Hong, WANG Xin. Production Prediction of Fractured Horizontal Wells in Tight Oil Reservoirs [J]. Xinjiang Petroleum Geology, 2022, 43(5): 580-586. |

| [3] | WANG Fei, WU Baocheng, LIAO Kai, SHI Shanzhi, ZHANG Shicheng, LI Jianmin, SUO Jielin. Inversion of Fracture Parameters and Formation Pressure for Fractured Horizontal Wells in Shale Oil Reservoir Based on Soaking Pressure [J]. Xinjiang Petroleum Geology, 2022, 43(5): 624-629. |

| [4] | XIAO Hanmin, LUO Yongcheng, ZHAO Xinli, ZHANG Haiqin, LIU Xuewei. Factors Influencing Productivity of Horizontal Wells With CO2 Inter-Fracture Flooding [J]. Xinjiang Petroleum Geology, 2022, 43(4): 479-483. |

| [5] | WAN Xiaolong, ZHANG Yuanli, FAN Jianming, LI Zhen, ZHANG Chao. Production System of Horizontal Well in Shale Oil Reservoirs of Chang 7 Member, Ordos Basin [J]. Xinjiang Petroleum Geology, 2022, 43(3): 329-334. |

| [6] | FAN Jiwu, XU Zhenping, LIU Lili, ZHANG Juan. Production Profile of Horizontal Wells in Strongly Heterogeneous Tight Gas Reservoirs in Sulige Gas Field [J]. Xinjiang Petroleum Geology, 2022, 43(3): 341-345. |

| [7] | LIU Jiaojiao, WANG Delong, LIU Qian, TANG Jing. Evaluation on Adaptability of Horizontal Well Development to Multi-Layer Tight Sandstone Gas Reservoirs [J]. Xinjiang Petroleum Geology, 2022, 43(3): 354-359. |

| [8] | WANG Liqiong, WANG Zhiheng, MA Yulong, ZENG Qingxiong, ZHENG Fan. Technologies and Application of Sidetracking Horizontal Well in Existing Wells in Sulige Gas Field [J]. Xinjiang Petroleum Geology, 2022, 43(3): 368-377. |

| [9] | DENG Zhenlong, WANG Xin, TAN Long, ZHANG Jigang, CHEN Chao, SONG Ping. Enhancing Oil Recovery of Tight Conglomerate Reservoirs by Asynchronous CO2 Huff and Puff in Mahu Sag [J]. Xinjiang Petroleum Geology, 2022, 43(2): 200-205. |

| [10] | ZHENG Jian, FU Yongqiang, CHEN Man, JING Cui, ZHANG Jing, ZHOU Hao, ZHANG Jiahao. Application of Vertical P⁃Wave Slowness in Porosity Evaluation of Shale Gas Reservoirs in Highly Deviated or Horizontal Wells [J]. Xinjiang Petroleum Geology, 2021, 42(zk(English)): 158-164. |

| [11] | LU Ting, WANG Mingchuan, MA Wenli, PENG Zeyang, TIAN Lingyu, LI Wangpeng. Fractured Horizontal Well Test Model for Shale Gas Reservoirs With Considering Multiple Stress Sensitive Factors [J]. Xinjiang Petroleum Geology, 2021, 42(6): 741-748. |

| [12] | CHENG Ning, GUO Xuyang, WEI Pu, HUANG Lei, WANG Liang. Inter-Fracture and Inter-Section Interference Modeling for Staged and Clustered Fracturing Stimulation in Horizontal Wells: A Case Study on Reservoirs of Badaowan Formation in Wellblock Ji 7 in Changji Oilfield [J]. Xinjiang Petroleum Geology, 2021, 42(4): 437-443. |

| [13] | YANG Liping, GE Jijiang, SUN Xiangyu. Experiment on Nanoparticle Active Oil Water Plugging Agent in Tahe Gas Field [J]. Xinjiang Petroleum Geology, 2021, 42(2): 218-223. |

| [14] | WU Mei’e, ZHANG Zhongjin, ZHANG Mei, PAN Youjun, XIE Shijian, CHEN Changxu. Stereoscopic Waterflooding Technology and Its Application in Niudong Volcanic Oil Reservoir [J]. Xinjiang Petroleum Geology, 2020, 41(6): 735-739. |

| [15] | LIANG Weiwei, DANG Hailong, CUI Pengxing, WANG Xiaofeng, HOU Fenchi, ZHANG Tianlong. Application of 3D Geological Modeling in Horizontal Well Development of Tight Sandstone Oil Reservoirs: A Case Study of Block S in Ordos Basin [J]. Xinjiang Petroleum Geology, 2020, 41(5): 616-621. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||